Clean air in your woodshop is crucial since it safeguards you and your tools. After sanding, sawing, and routing, particle-filled air increases the risk of health problems, damaged tools, and fire accidents. Properly installing a shop air filter guarantees that your workspace meets all safety, productivity, and environmental requirements

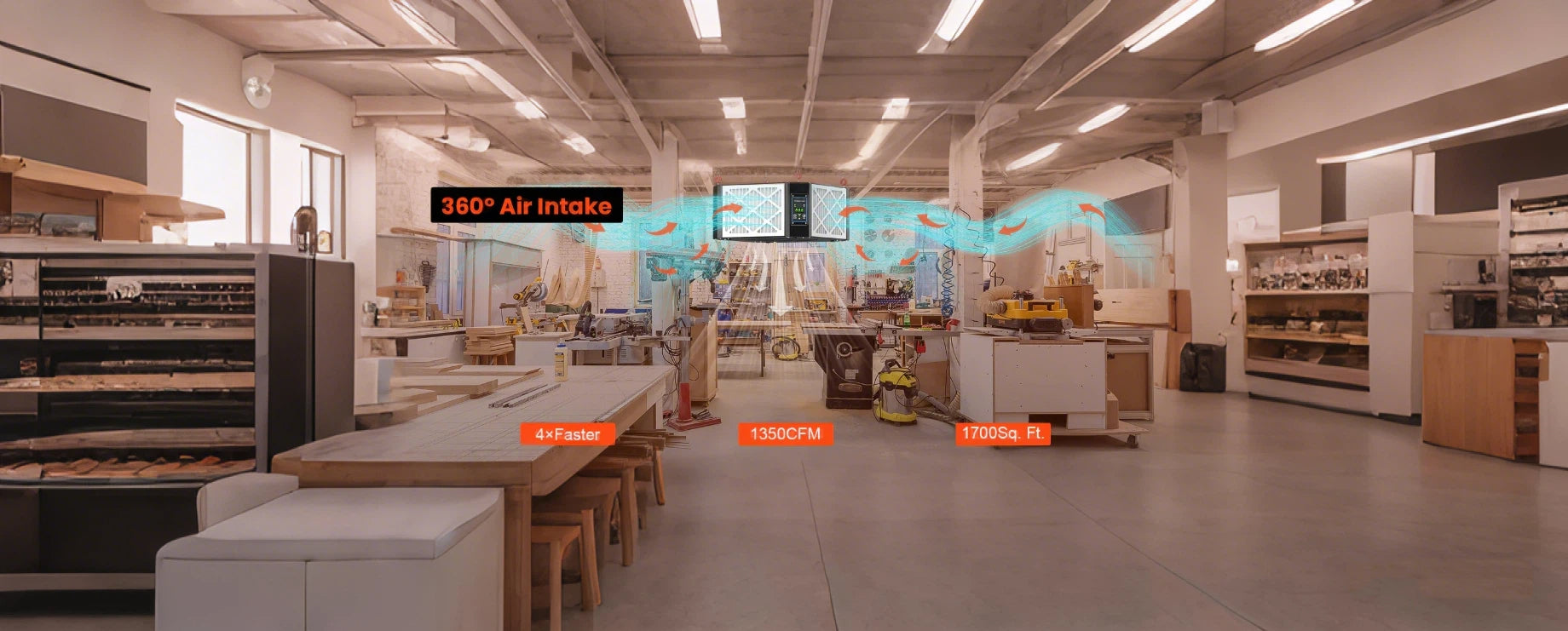

You’ll find tips on installing an air filter in your woodworking shop and information on the most effective models, such as the 360 Degree Intake Air Filtration System.

Why Hang Air Cleaners in a Woodworking Shop?

The best method for managing dust in the air is to set up an air cleaner in a permanent, ceiling-mounted position. Properly installed, your woodworking air filtration system will effectively remove dust from the air.

-

Continuously filter out fine particles.

-

Improve visibility and cleanliness.

-

Reduce the accumulation of dust on surfaces and tools.

-

Prolong the life of other dust collection systems.

Walls-mounted air filters have wider coverage, distribute air throughout the work area, and minimise the required space on work surfaces.

Choosing the Right Spot to Hang Your Air Filter

Location matters to maximize efficiency. The air filter should be mounted in an open area where dust often settles. A suspended air cleaner placed in the middle of a woodworking shop works best because of the generally poor natural ventilation.

If you operate more than one machine in your workshop, install the air filter close to the equipment that creates the greatest amount of dust. It's beneficial to place the system so that air moves from one side of the shop to another for improved dust collection.

The 360 Degree Intake Air Filtration System is made to be suspended from the ceiling and even collects dust throughout the workspace.

Ventilation Tips for Odd-Shaped or Multi-Zone Shops

Some woodshops and workspaces can have various-shaped layouts or be divided into different zones. Some shops are arranged in different areas or sections. You can install additional filters or reposition them in these situations for optimal airflow. Place a filter unit inside each corner of an L-shaped workshop or at opposite ends of a room partially separated by a wall or partition. Place the only filter in a way that allows it to draw air along the longest path possible. Using this method boosts the efficiency of air circulation and aids in capturing dust particles before they fall to the ground.

Tools and Materials Needed

Before installation, gather the following

-

Tape measure and pencil.

-

A stud finder is necessary to fasten the filter to the wood framing in the ceiling.

-

Sturdy mounts that can withstand the unit’s weight.

-

Drill and screws.

-

A pair of safety glasses and a dust mask to protect yourself from particles.

The instructions for your filtration system will outline the minimum space and mounting specifications. This will ensure the ceiling isn’t put under unnecessary stress.

Installation Steps for Hanging a Shop Air Filter

Measure and Mark

Measure the middle of your working area to determine where to place the unit. Using a pencil, clearly indicate where each ceiling joist is on the surface above.

Attach Mounting Hardware

Secure the unit to the ceiling using the screws or bolts provided by the manufacturer. When dealing with wooden joists, installing screw hooks designed for heavy loads is suitable. Lag bolts or anchors designed for heavy loads are the best for metal studs or trusses.

Hang the Unit

Install the unit using chains or brackets that can be adjusted to change the height. It should be suspended approximately 6 to 8 feet from the floor.

Check Stability and Power Connection

Make sure the filter is installed evenly and firmly in place. Next, connect it to an appropriate power source. A few models provide a remote control or timer, so check these features to ensure they work correctly.

When to Use and Care for Your Filter

You should let the filter run for 30 minutes following your work session. Using the air cleaner for 30 minutes beyond your project allows it to collect most of the remaining particles. Depending on how often the filter is used, it should be replaced monthly or every two to three months when used less frequently.

Each shop air filter from Abestorm includes a multi-stage filtration system and monitoring lights that help you track when the filters need to be replaced or cleaned.

Should You Install Your Shower on the Wall or From the Ceiling?

Install a filter on the ceiling for optimal performance or choose a wall-mounted filter for smaller workshops or garages. Placing them on the wall leaves much room on the ceiling, allowing air to flow out of the filter first. Nevertheless, a wall-mounted filter doesn't provide the same fresh air for the entire workshop as ceiling-mounted filters.

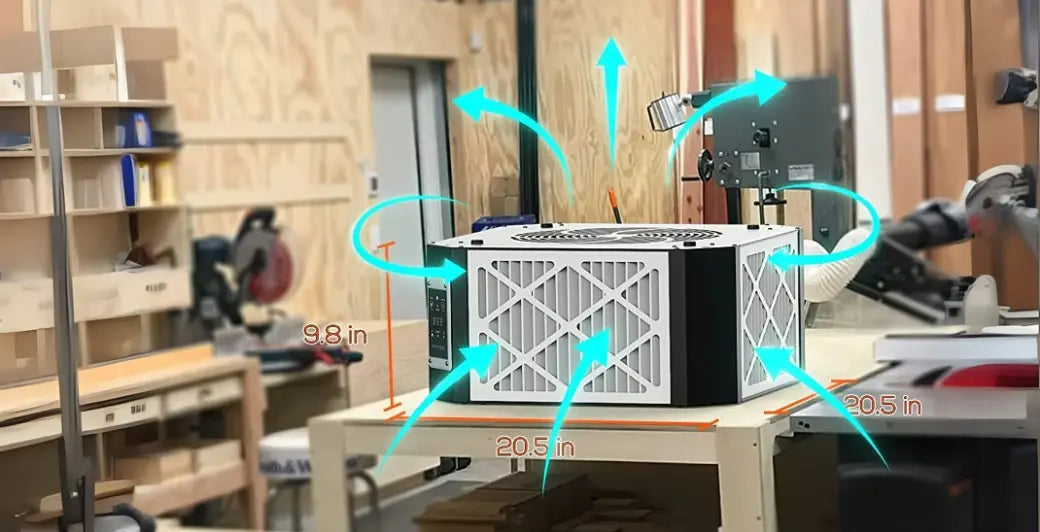

The Abestorm DECDust 1350iG may be adapted to different layouts according to the specific space in your workshop.

Using Your Filtration System Together with Your Existing Dust Collection System

For fresh and clean air in your workshop, it's recommended that you use both a dust collection system and air filters. Vacuums collect large debris, while a ceiling-mounted filter handles the smallest particles.

Consider reading The 6 Most Popular Wood Shop Dust Collectors in America to choose the best dust collectors to pair with your filtration unit. Combining the two systems will considerably improve your work environment and help prevent health issues.

Why the 360 Degree Intake System Stands Out

This air filtration system has been designed specifically for woodworking shops. Its 360-degree air intake allows quicker and more consistent filtration of particles in the atmosphere. The result is that your shop will have even coverage, and any dust particles will be collected more efficiently.

Built to withstand daily use in any woodworking shop, it requires minimal maintenance and works efficiently on every piece.

Final Thoughts

Installing an air cleaner as part of a DIY project can enhance your shop's safety and health. Constantly exposed to dust will gradually harm your health, particularly in closed workspaces with inadequate air circulation. Installing a reliable shop air filter like the 360 Degree Intake System from Abestorm is a smart investment in your tools and well-being.

Using the correct placements, mounting tools, and routine maintenance will guarantee that the filter always provides clean air while you work.

Enjoy your work as much as ever, without any irritating particles.

Shop For Dehumidifier

Abestorm 170 PPD 2,100 Sq.Ft Commercial Dehumidifier with Pump and Drain Hose | Hurricane 800

Abestorm 180 PPD 2,300 Sq.Ft Commercial Dehumidifier with Pump and Drain Hose | Hurricane LGR85

Abestorm 264 PPD 3,000 Sq.Ft Commercial Dehumidifier with Pump and Drain Hose | Hurricane 125P

Abestorm 180 PPD 2,300 Sq.Ft Commercial Dehumidifier with Pump and Drain Hose | Hurricane 850