Selecting the proper air filtration unit is essential for ensuring your woodworking shop remains clean and safe for everyone. Unchecked wood dust in the air can adversely affect your health, equipment, and workspace safety. A suitable filter captures even the smallest particles, ensures good air quality, and improves work efficiency. How can you ensure you choose an air filter that adequately covers the space?

The following information will help you determine the correct size of air filtration unit you need, explain how to choose a trusted model, and show why woodworking experts rely on the 360 Degree Intake Air Filtration System.

Why Air Filter Size Matters in a Woodworking Shop

Wood dust tends to stay suspended in the air for quite some time. If your shop air filter is too small, it won’t effectively capture fine particles.

You should select a filter that can remove air from your room at the same rate as it circulates within the space. This guarantees that the entire air in your shop is cleaned several times over during each hour. Having the right size means less dust settling, reduced risks to your health, and improved durability for your equipment.

Familiarizing yourself with Air Changes per Hour (ACH)

ACH refers to the number of times the amount of air in your shop goes through the filter within an hour. A woodworking room should aim for 6 to 8 Air Changes per Hour. Choosing a unit with a higher ACH is ideal when performing demanding operations.

To calculate the right air filter size, use this formula:

(Length × Width × Height) × ACH ÷ 60 = Required CFM

Here’s what each part means:

-

Length × Width × Height: Total cubic footage of your shop

-

ACH: Air changes per hour (6–8 recommended)

-

60: Number of minutes in an hour

-

CFM: Cubic Feet per Minute, which is the unit of airflow capacity

Example Calculation for a Medium-Sized Shop

Let’s say your woodworking shop is 20 feet long, 15 feet wide, and has an 8-foot ceiling.

20 × 15 × 8 = 2,400 cubic feet

If you want 6 air changes per hour:

2,400 × 6 ÷ 60 = 240 CFM

You’ll need a unit that delivers at least 240 CFM. To be safe, aim for 320–400 CFM for heavier dust-producing projects. Always choose a slightly larger CFM rating rather than risk going too low.

How Room Shape and Equipment Affect Your Filter Needs

The design of your woodworking space can affect the effectiveness of your air filtration system. A large, unobstructed space makes keeping the air flowing freely throughout the shop simpler. Installing taller and wider equipment or furnishings can limit your shop's air distribution. Consider upgrading your filter or adding specialized filtration points.

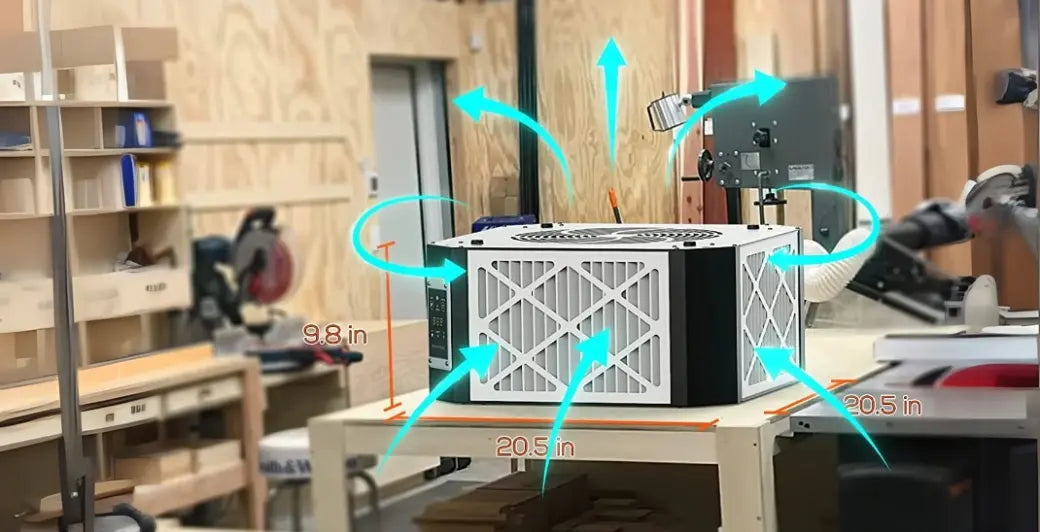

The 360 Degree Intake Air Filter System is preferred because it can capture dust from every part of the room. It ensures even ventilation and better dust capture in every part of the shop.

Ceiling Height Considerations

Many woodshops have ceilings higher than 8 feet. A shop with a ceiling of 10 or 12 feet produces much more air that needs to be filtered.

For instance, a 20 × 15 room with a 12-foot ceiling is:

20 × 15 × 12 = 3,600 cubic feet

To achieve 6 air changes per hour:

3,600 × 6 ÷ 60 = 360 CFM

You’ll need a stronger system than you would in a lower-ceiling space. Simply using square footage isn’t enough—you need to calculate volume.

Filter Placement and Efficiency

A filter won’t work properly unless it is installed in the proper area. Filters should be placed:

-

At a distance of several feet from the ceiling.

-

Away from walls or obstructions.

-

In central or high-dust areas.

-

Orient the intake so it draws dust from the most polluted areas.

This guarantees the filter collects all dust and forces air to move smoothly throughout the room. Place multiple air filters on opposite sides of the shop so air flows evenly throughout the entire space.

Using Air Filters with Other Dust Control Tools

A shop air filtration system works best when used in conjunction with a dust collector. The dust collector collects large dust particles around heavy-duty machines, and woodworking shop air filtration system to clean up what lingers in the air.

Running both systems together lowers the amount of particles in the air, preserves your health, and maintains a safe environment throughout your work area.

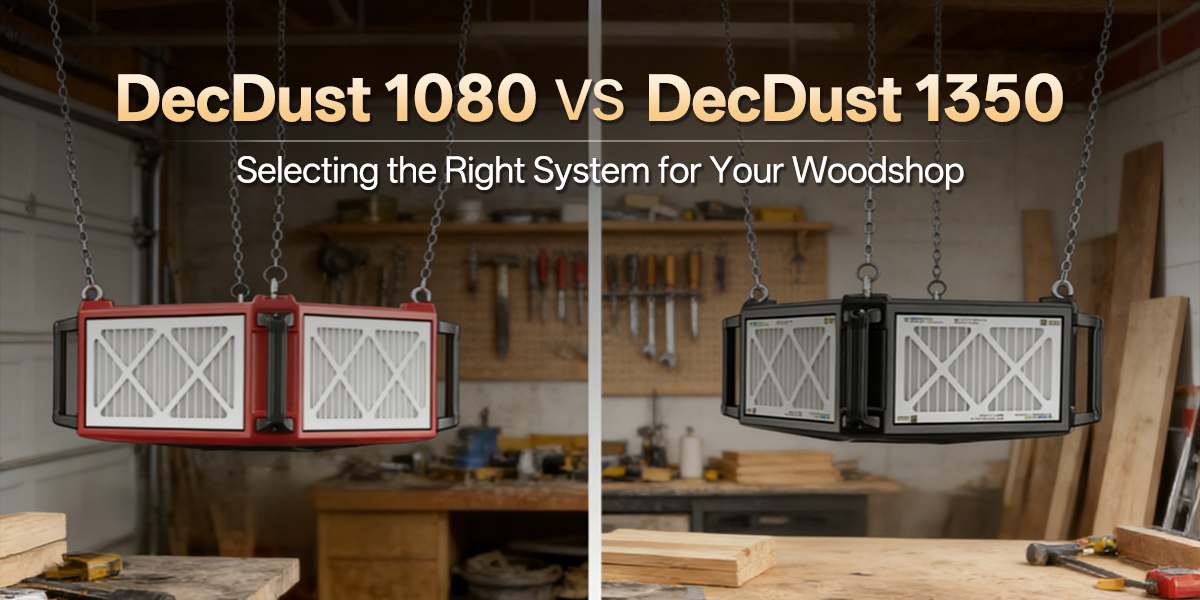

Choosing the Right Model for Your Needs

Several models are designed for occasional use in compact home shops. The 360 Degree Intake System is designed for continuous shop work use. This unit provides efficient airflow, strong suction, and energy savings essential in a work environment with extended hours.

Look for a model that includes all the following features:

-

Enough airflow as determined by your needs

-

Easy-to-change filters

-

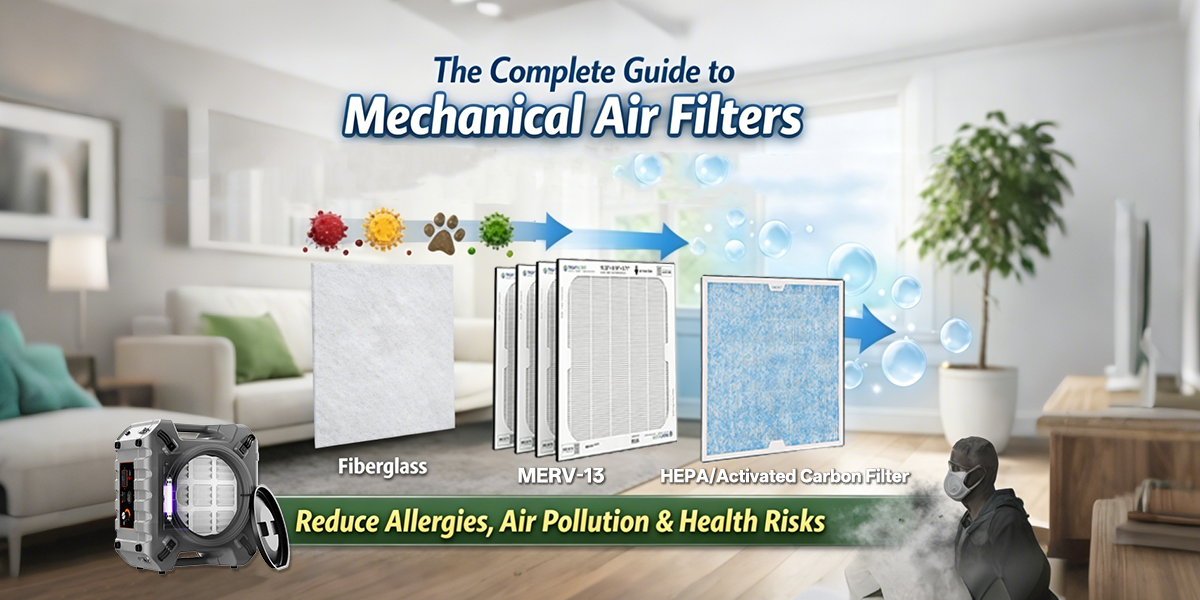

Multi-stage filtration

-

Specifications to minimize noise levels for workshop settings

-

Sturdy suspension mounts or brackets

When to Consider Multiple Units

If your shop is more than a thousand square feet or divided into several rooms, you'll likely need more than one filter. Your best option is to use two smaller units near opposite ends of the shop to allow air to move smoothly throughout the space.

Another option is to add a small filter to your wall near where you use your dust-producing equipment.

Final Thoughts

Getting the right size for your air filtration unit is essential to achieving good air quality in your woodworking space. Measure your room, select the right ACH level, and choose a filter with enough airflow for your workspace. Select a slightly larger unit if you’re unsure which size would work best for your woodshop.

A system as efficient as the 360 Degree Intake Air Filter System ensures cleaner air, more healthful working conditions, and greater security for each of your projects.

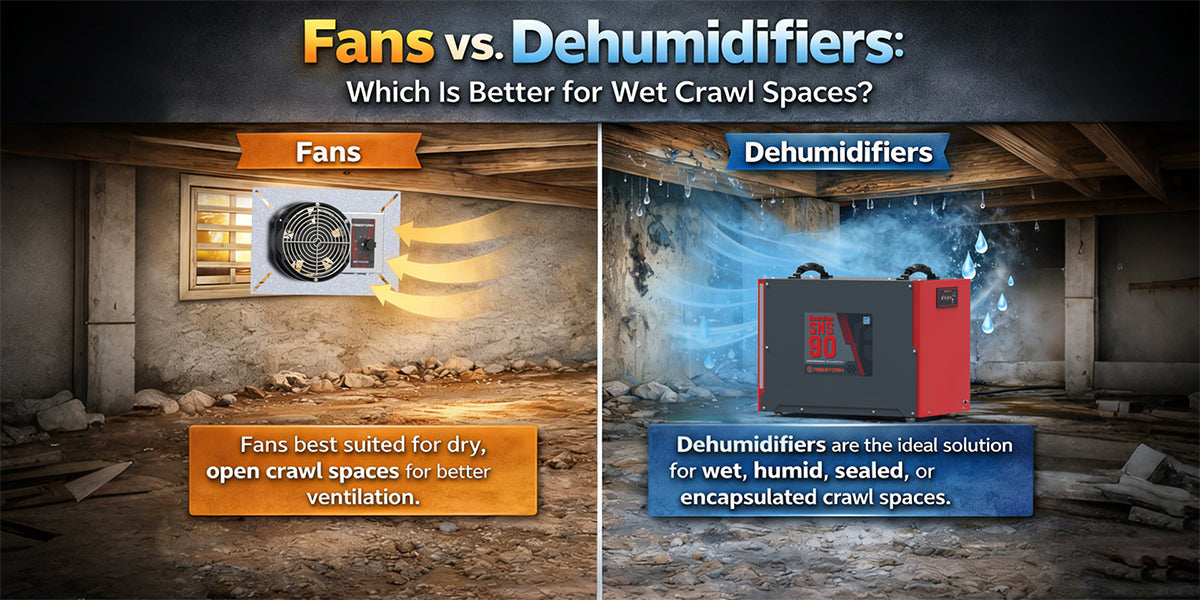

Shop For Dehumidifier

Abestorm 170 PPD 2,100 Sq.Ft Commercial Dehumidifier with Pump and Drain Hose | Hurricane 800

Abestorm 180 PPD 2,300 Sq.Ft Commercial Dehumidifier with Pump and Drain Hose | Hurricane LGR85

Abestorm 264 PPD 3,000 Sq.Ft Commercial Dehumidifier with Pump and Drain Hose | Hurricane 125P

Abestorm 180 PPD 2,300 Sq.Ft Commercial Dehumidifier with Pump and Drain Hose | Hurricane 850