One of the main challenges that a lot of industrial spaces and workshops have comes in them form of workshop humidity control. Yes, dust and high humidity levels can tend to be very problematic, and something you want to avoid. Not only can they hamper products and items stored inside the warehouse, but they also lead to issues for workers. That’s why you always want to find great strategies to circumvent that, like using an industrial dehumidifier.

Why humidity and dust are major issues in workshops?

Generally, water and dust tend to be problematic for industrial spaces. Wood absorbs moisture, metal rusts, electronics get damaged, paint and finishes will fail completely if the moisture levels are too high.

The same thing can be said when it comes to dust. Usually, dust will lead to respiratory problems, and suspended dust can be combustible, especially in the case of woodworking. If the company uses sensors or calibration tools, their accuracy will be affected by dust. In general, you want to keep dust and humidity levels in a workshop at a low level, where possible. That can circumvent issues, and provide better overall results.

Effects on materials, tools, and worker health

Will dust and humidity bring worker health issues? Of course, because excess humidity always leads to fatigue, discomfort and respiratory problems. Not only that, tools that are electronic in nature will stop working most of the time. And to make things even worse, metal components can get corroded, which is the last thing you want. Even lubricants will break down faster if the environment they are in is very humid.

Plus, if the space has wood, those wooden products will distort, contract or expand, depending on the situation at hand. And the same thing is valid when it comes to dealing with surface cracking or grain problems. Even the colors won’t be absorbed properly most of the time. You need to find a way of addressing this problem, otherwise you will encounter a variety of challenges that are very hard to face.

Integrating dust collectors and dehumidifiers for balanced air quality

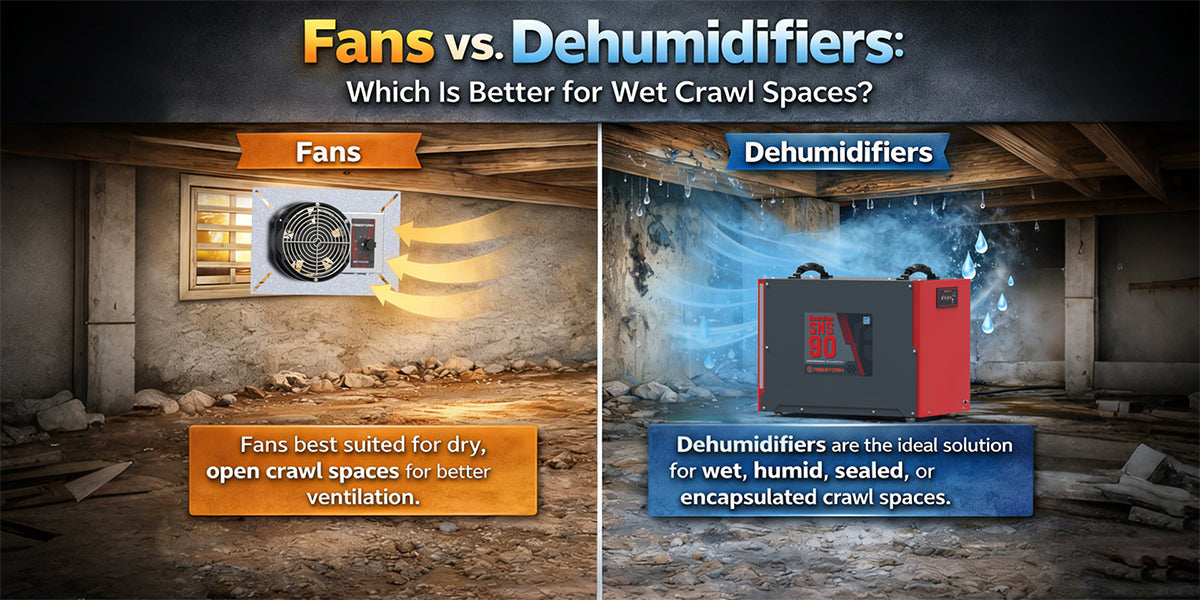

What you want to do when you have an industrial environment with high humidity levels and dust is to use dehumidifiers and dust collectors. The role of a dust collector is to capture airborne particles via filters, ducts or hoods. And then you have the industrial dehumidifier that will remove moisture from the ambient air. Both of them are ideal if you want to get rid of unwanted dust particles and high humidity, so keep that in mind.

Of course, you do need to think of other things as well, including:

- Separate the high moisture zones when you can, so you can have better control over humidity levels

- Additionally, it makes sense to coordinate the ventilation rates in order to balance pressure

- Design the ducting system in such a way that the clean/dehumidified air circulates across all areas in a uniform manner.

- Installing HEPA stages and pre-filters is always going to help trap fine dust, something that’s extremely useful.

Practical layout ideas

When it comes to ducting, try to use the shortest path principle, since the longer the ducts are, the more obstructions and issues arise. Calculate the static pressure and focus on branch balancing where you can, as it will help you quite a lot.

Go with a multi-stage filter setup too. You should have a coarse pre-filter, a fine filter and a HEPA or even a cartridge filter. As for the dehumidifier, it makes sense to place it in a central spot and you can use ducted industrial solutions if you have a large facility. For those cases when we talk about a localized workshop, using a portable unit can actually help, and it could improve the experience.

Maintenance and safety best practices

You should make sure that you keep the humidity and dust levels under control. Here are some ideas:

- If you use a dust system, try to empty the collection bins every day and inspect the ducts/joints every month. Replacing the filters or at least cleaning them is also of pivotal importance. And yes, ground all the metal ducting, as it will allow you to prevent any explosion and static discharge, which could become an issue later on.

- For dehumidifiers, you want to clean the filters and condenser coils every month. You also want to check the drainage systems and inspect gaskets/seals where possible, so there are no air leaks. And of course, you do want to schedule the calibration of humidistats where you can, so the readings can stay accurate.

- Lastly, make sure that you keep the health and safety compliance. Ensure that all the fire suppression systems are functional, stick with the OSHA dust exposure limits, and use PPE equipment where possible, to limit any side effects or downsides.

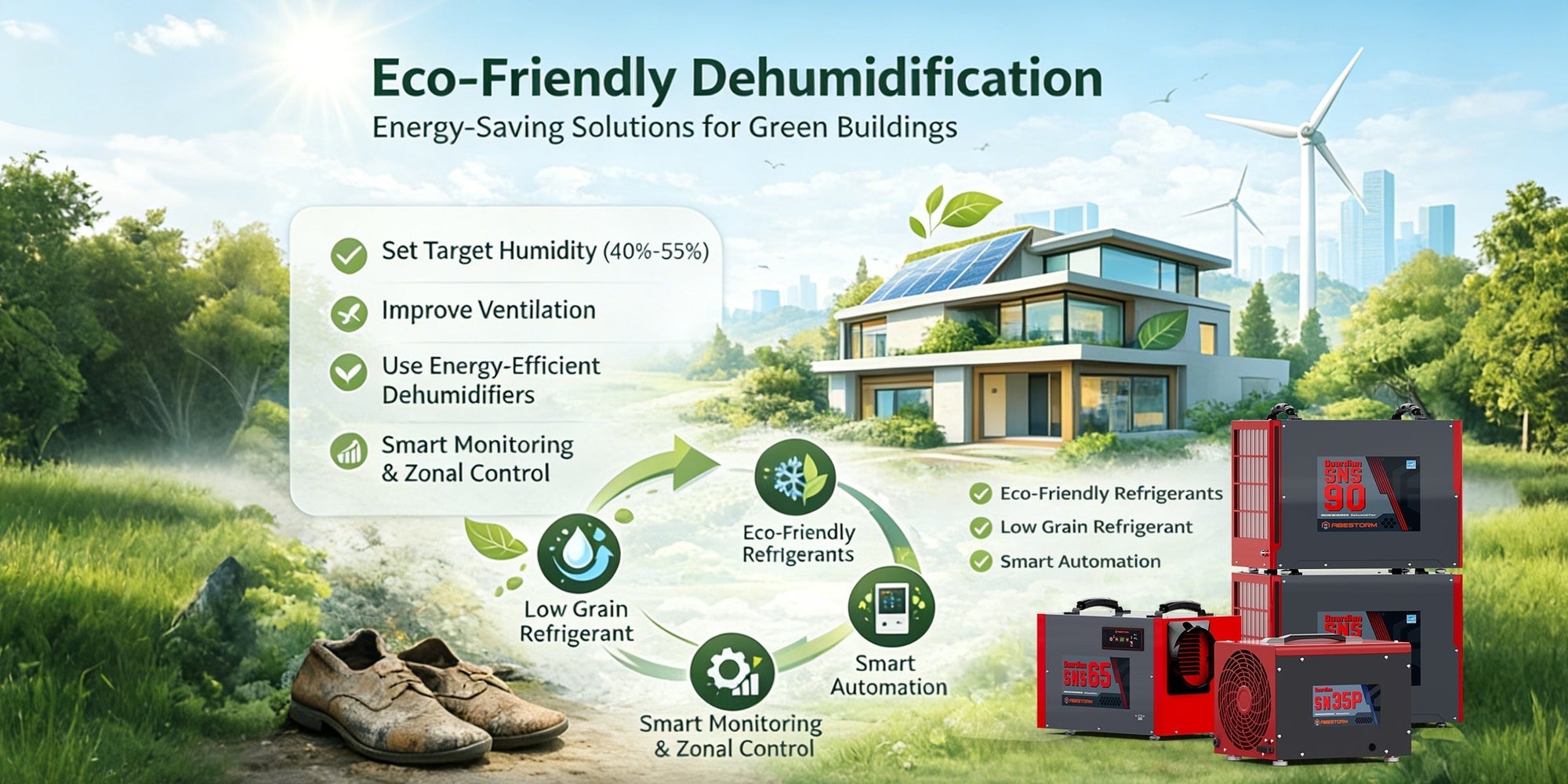

Cost-saving and energy-efficient strategies

There are also a few other things that you can do to save money and lower energy costs. For example, you want to clean filters and lubricants, along with having smart humidity control. Using variable speed drives will also help quite a lot, and it does help to have heat recovery, along with good air recirculation. All of that stuff is super important, and it will affect the overall costs. Plus, even simple things like the equipment selection or using renewable energy, those can end up making a huge difference in the long run.

Conclusion

We believe it’s a very good idea to try and keep humidity and dust levels as low as possible in industrial environments. These tips and ideas shown above will always be useful, especially in these very specific situations. Once you start implementing such solutions, it will be not only easier to manage, but you can also avoid a lot of challenges and potential issues. Once you handle that appropriately, it will bring in a much better experience. Plus, you do want to keep the equipment and people safe, and this is the right approach!

Shop For Dehumidifier

Abestorm 170 PPD 2,100 Sq.Ft Commercial Dehumidifier with Pump and Drain Hose | Hurricane 800

Abestorm 180 PPD 2,300 Sq.Ft Commercial Dehumidifier with Pump and Drain Hose | Hurricane LGR85

Abestorm 264 PPD 3,000 Sq.Ft Commercial Dehumidifier with Pump and Drain Hose | Hurricane 125P

Abestorm 180 PPD 2,300 Sq.Ft Commercial Dehumidifier with Pump and Drain Hose | Hurricane 850