In order for woodshops to stay competitive, it’s very important to invest in great equipment, but also in high efficiency air filtration. That’s because the entire workspace needs to be dependable, it needs to keep the team safe, as they work on a multitude of projects. Sure, these shops must be low-maintenance, so ideally, you want air filtration maintenance systems that you set and forget about them. So it helps if you’re up to date with the latest woodshop dust control trends. We’ll cover the latest trends in this niche below.

Why Woodshop Dust Control Is Gaining More Attention in 2026?

These days, businesses need to be competitive, but they also have to comply with the industry and more specifically, health regulations. That’s why woodshop dust control has become extremely important. You need to make sure that your woodshop takes good care of dust removal, otherwise it can prove to be extremely challenging.

- In 2026, health awareness has reached an entirely new level. Over many years, research has shown that airborne wood dust can lead to asthma, chronic respiratory problems, skin and eye irritation, but also an increase in long-term risks from dust exposure.

- The industry standards and regulations are becoming tighter and tighter. Whether we are talking about small or large woodshops, they need to show an effort in regards to controlling fine dust. That’s where a woodshop air filtration system becomes a necessary investment.

- Another thing to note is that in the current times, cleanliness and productivity are linked. Simply put, less dust settling leads to fewer cleaning interruptions and an increase in productivity. Workers can also focus better due to fewer contaminants present, and there’s an improved comfort even if employees deal with long working hours.

The woodworking industry can have tight deadline and it certainly has its fair share of challenges. However, it’s imperative to focus on safety, and that will automatically have a great boost productivity-wise. Once you start investing in that, it will lead to much better results, and business growth. So it’s more important than ever to create a healthy, professional and dust-free environment, as much as possible.

High-Efficiency Air Filtration as the New Standard

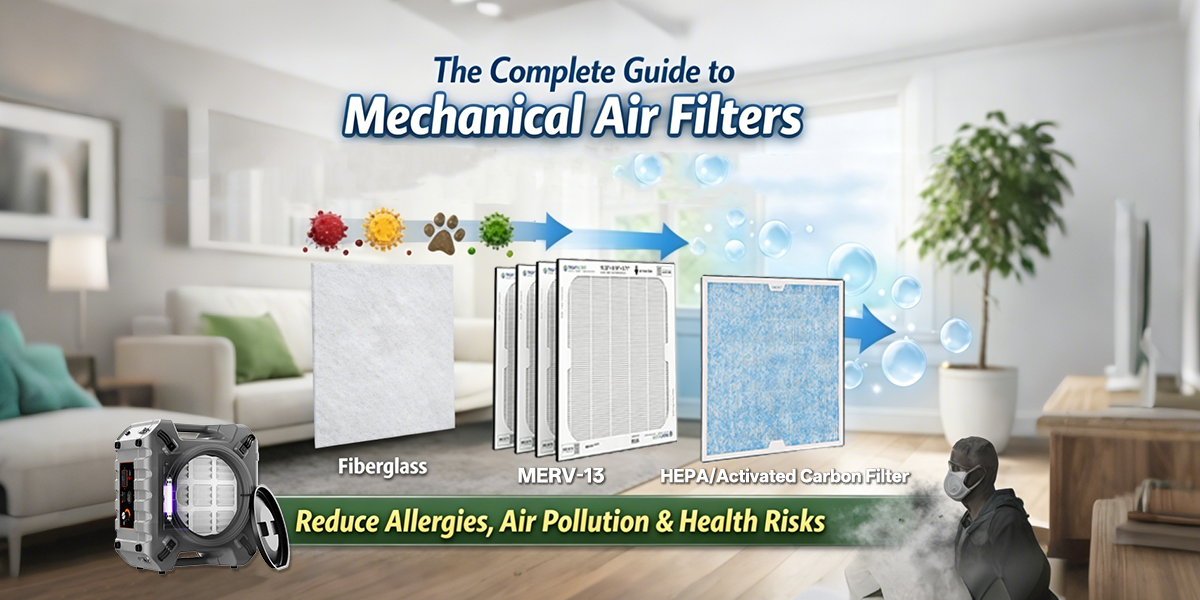

These days, high-efficiency air filtration has become the new standard, for a very good reason. HEAF is important because it involves multiple ways to increase air cleanliness. These include multi-stage filtration systems, fine particle capture systems, consistent performance and optimization to improve airflow, as well as filtration, keeping everything balanced.

Fine dust is the primary target because dust collectors can easily remove large wood chips, but dust is very difficult to manage. Sanding dust, sawdust and dust stirred by movement, all of that remains up in the air. And if it’s not removed, all that dust and small particles will end up in people’s lungs. That leads to severe irritation and pulmonary problems down the line. The role of a high efficiency air filtration system is to help eliminate those problems and keep the entire environment safe.

Of course, these are only some of the trends, there are many others, including:

- Ambient filtration and ceiling-mounted systems are increasing in popularity. These systems are great because they are allowing you to save space, and they also help improve the air circulation. Not only that, but there’s reduced interference with the workflow, and continual background filtration.

- Compactness is very important for these dust control systems. Many woodshops are very compact, and that’s why any woodshop air filtration system needs to be compact and small. Many of the newer models within this niche are following the trend.

Low-Maintenance Air Filtration Systems on the Rise

One thing to note in 2026 is the fact that shop owners have become a lot more selective. They want high efficiency air filtration systems. However, they don’t want to worry about constant air filtration maintenance. Instead, they want a streamlined, faster and more consistent system in place.

Businesses in this niche have certain frustrations with older systems. These can include frequent filter changes, filter replacement costs being too high, not to mention performance drops and a very challenging disassembly process. That’s why they want a newer air filtration solution which is not going to require a lot of maintenance.

Low-maintenance systems are great in many ways, because they offer special features, including:

- Long-life, washable pre-filters. Old filters were not easy to remove and wash, newer, low-maintenance systems are solving this problem.

- Now, there’s a tool-free way of accessing filters. Needless to say, before the newer models, it was extremely difficult to access and change filters.

- The airflow system is improved, so it can help reduce any premature clogging.

- There are also clear indicators to show what’s the current condition of the filters. That will let you know exactly when you have to change filters, without continually worrying about their condition.

Woodshops need less downtime related to maintenance, that’s why investing in durable and high quality systems from the beginning matters a lot. These low-maintenance systems help provide continuous daily operation and they keep the maintenance schedules predictable. Plus, they offer a smart design, while also keeping the technology approachable and easy to understand.

The Return of Durable and Long-Lasting Filtration Equipment

A very powerful, yet expected shift in the industry right now is the focus on durability. Disposable solutions were fine for a while, but they are not as good at this time. Instead of treating the air filtration machines as a disposable solution, companies in the woodworking sector want an investment that will last for a very long time.

That’s why the most important things to consider within this niche right now are the heavy duty housing systems, but also the filter systems, and durable motors that can withstand thousands of hours of work. It’s clear that durability is not just something good to have, it’s a must-have in order for a woodshop to grow and surpass competitors.

Aside from that, there’s also a lot of focus on cost control and sustainability. Durable equipment is meant to reduce waste, while also lowering the operational costs and minimizing the environmental footprint. That’s where a high efficiency air filtration system can shine. It’s meant to offer great reliability, ease of use, while also delivering better ways to control dust within the work space.

What woodshop air filtration system should you buy?

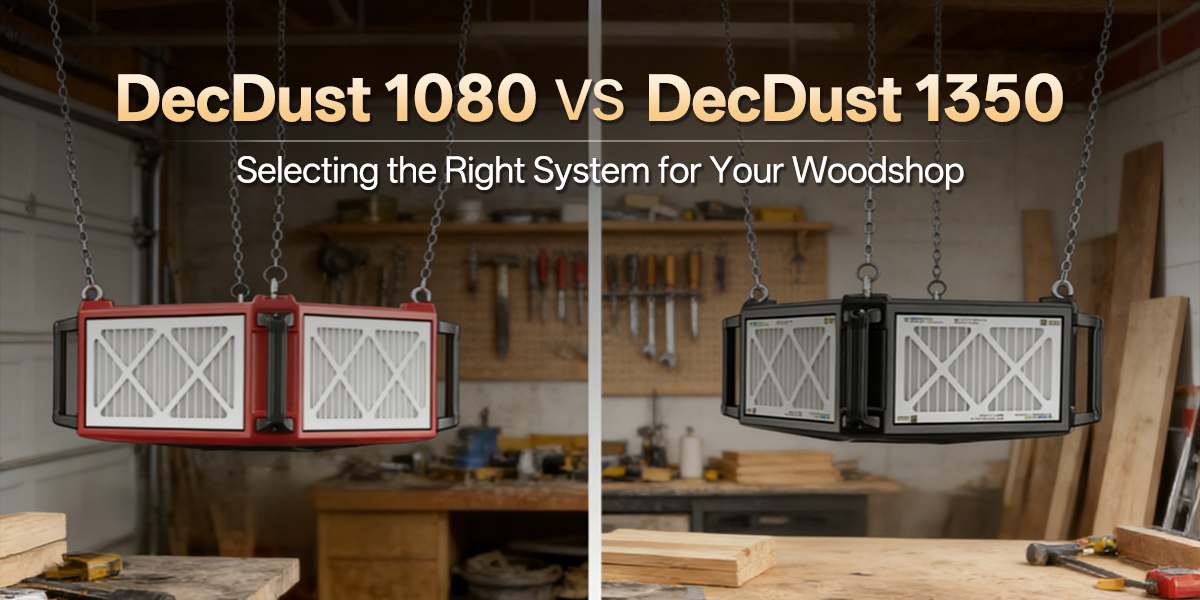

That depends on what you are looking for. The DecDust 1350 is a great option if you’re looking for a great, high airflow capacity, a robust construction, and also an efficient system for multi-stage filtration. Then, you also have a lower maintenance requirement when compared to older designs. That makes it excellent especially for medium-sized and larger shops.

There’s also the DecDust 780, which is actually a very powerful air filtration system. It has a 3-sided intake air system that helps with the dust collection capacity. You also have a 2-speed air filtration system, MERV-11 micron filters and a remote control system. That makes it much more seamless to work within these spaces, and you’ll have excellent results.

Low-maintenance and high-efficiency: ideal for the 2026 woodshop

A modern woodshop doesn’t have the luxury of experimenting and trying out things. Clients expect reliability and consistency. That’s why it’s extremely important to offer those, hence the reason why an air filtration system is important. Aside from that, companies also expect:

- The woodshop needs to have a dust control strategy. That involves an air filtration system, machine-level dust collection, adequate airflow, along with equipment that’s very easy to maintain.

- Additionally, it’s expected for the team to receive education and training when it comes to enhanced safety. Woodworkers need to know about the filter lifespan, micro ratings, how to change filters, etc. Adequate education can go a long way.

- Moreover, it’s important for the woodworking company to think of investments in quieter operation, better filter materials, etc. Future-proofing your business and removing the need for continual maintenance is always going to help.

Conclusion

Dust control in woodshops isn’t just a fad. It’s a necessity, and something that companies need to do. Investing in a high efficiency air filtration system is crucial, since it can help remove any dust particles, while keeping workers healthy. And on top of that, it becomes easier to comply with the industry requirements and regulations. Products like the DecDust 780 or DecDust 1350 are clear solutions that help optimize the airflow, keep dust particles away, while enhancing your company’s growth. If you want your woodshop to reach new heights, a good air filtration system is a must-have in 2026 and beyond.

Shop For Dehumidifier

Abestorm 170 PPD 2,100 Sq.Ft Commercial Dehumidifier with Pump and Drain Hose | Hurricane 800

Abestorm 180 PPD 2,300 Sq.Ft Commercial Dehumidifier with Pump and Drain Hose | Hurricane LGR85

Abestorm 264 PPD 3,000 Sq.Ft Commercial Dehumidifier with Pump and Drain Hose | Hurricane 125P

Abestorm 180 PPD 2,300 Sq.Ft Commercial Dehumidifier with Pump and Drain Hose | Hurricane 850