Getting a woodshop air filtration system is an excellent idea, and it can provide you with an outstanding return on your investment. Not only that, but woodshops are known for being unhealthy environments, filled with sawdust and fine particles that are dangerous for people working there. Hence the reason why you want to invest in various types of air filtration. Not only will it improve the health of employees, but it will also streamline and boost the productivity as well.

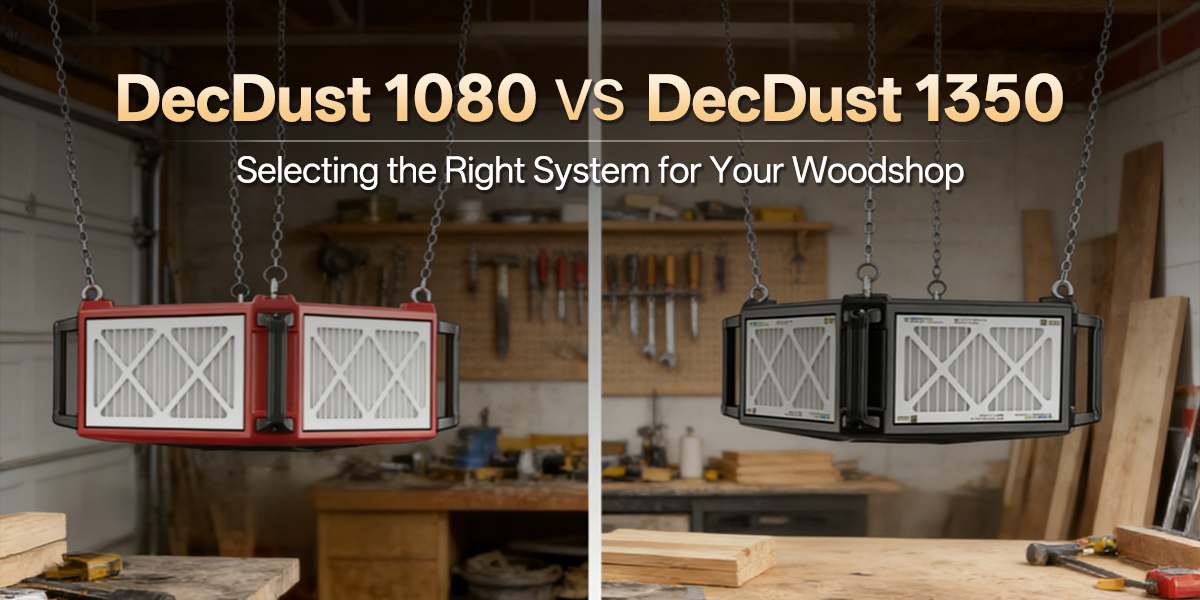

Why Choosing the Right Air Filtration Model Matters in Woodshops?

The truth is that you want a woodshop air filtration system which keeps the place safe and which helps you enhance the way people work. The reality is that you want growth, effectiveness and a very good return on investment. If you don’t match the filtration system to the shop size, you won’t have good coverage, overworked filters and the long-term costs will be a lot higher than expected. That’s why addressing those challenges and concerns is a crucial aspect to keep in mind here.

Key Factors Influencing Air Filtration System Selection

When you want to get a woodshop air filtration system, your focus has to be on a multitude of factors. After all, quality matters, but you also want great efficiency and all the other necessary features. With that in mind, here’s what you need to focus on:

- The airflow should be great, a higher CFM will mean quicker cycling through filters, but more airflow will be required if you have a heavy dust load environment, for example. The DecDust 1350 can go up to 1350 CFM, whereas the 1080 will go up to 1080 CFM. That means the former is good for a smaller workshop, whereas the 1350 is better if you have a larger space to work with.

- The intake design and its coverage area matters as well. If you choose the DecDust 1080, this unit has a 270-degree design. With the DecDust 1350 model, you have a 360-degree approach which is great if you want to pull air from all sides.

- Filtration efficiency matters just as much. In the case of these 2 DecDust models, both have MERV-11 filters, which can easily deal with the fine particles, including the smallest 1 micron ones.

- Think of the control features you can get as well. Both of these models have a panel control or remote. That means you will find it easier to control the timer and speed, among many others. The DecDust 1350IG even has extra features like environmental sensing or ionization, which could be an option.

- The installation process also matters quite a lot here. Ceiling mounting or an elevated placement is required here, because it will improve the intake and overall performance. Once you start doing that, it becomes a much better product to consider using, so use that to your advantage.

Clearly, there are a variety of different features that you want to keep in mind when it comes to dealing with this type of product. But the most important thing is to really take your time, prevent any rush, and focus on streamlining the way everything works. Both the DecDust 1080 and 1350 can be great purchases, it depends on the use case and the features you are looking for.

DecDust 1080 vs DecDust 1350: Features and Ideal Applications

When it comes to use cases, it always depends on where you want to use the product and how. The DecDust 1080 is ideal if you have a smaller woodworking shop where you generate dust moderately, not at a very high speed. It can also be good for workshops where the airflow is important, but not crucial. Simply put, this is ideal where you have a balance of a compact footprint and proper performance.

Then there’s the DecDust 1350, which is great for multiple workstations and larger woodshops. If the environment features a lot of cutting, tool operation or heavy sanding, you will generate a lot of dust and fine particles. That’s where the DecDust 1350 will shine the most. Plus, if you need wider coverage and fast air cycling, this might end up being right up your alley.

Common Selection Mistakes and How to Choose Correctly

There are many different misconceptions when it comes to choosing the right types of air filtration systems. And that’s why we are here to rectify them:

- Choosing the smallest unit by default tends to be normal for some people, because they think it’s quieter and less expensive. But the truth is that you want a unit with enough CFM to tackle your entire home.

- Ignoring the coverage area is also an issue. You should target 8-12 air changes per hour and also calculate the cubic footage of your woodshop as well.

- Another thing that gets ignored is the maintenance requirements. Ideally, the filtration system should have filters that are easy to replace, and it should make your maintenance routine easier to do, where possible.

- The same thing is valid when it comes to obstructing the unit with stuff. If you have items in front of the woodshop air filtration system, it will not work as good as it should. Remove obstructions, and things will be a whole lot better.

Deciding between the DecDust 1350 and DecDust 1080 can be tricky, but there are a few important things you can do in order to streamline this process. Ideally, you want to:

- Evaluate the dust load, if you have a lot of dust to tackle, a larger unit is usually preferred.

- On top of that, you also want to think of any future needs and possible expansions. The unit you got now might be fine, but in the future you might need an upgrade. If that’s the case, going the extra mile with a more powerful unit now will help you save money.

- Always measure the shop volume. A bigger space will always get to benefit if you have a higher airflow, so that’s extremely important to keep in mind.

- Think of maintenance requirements as well. The best air filtration machines are the ones that have simple filter replacement, because you don’t have to worry about severe maintenance or any requirements of that nature.

- Assess the feature needs and control requirements. Thankfully, both of the models have remote control. But things like ionization or timers are also something to think of as well.

Conclusion

Cleary, it makes a lot of sense to invest in a high quality woodshop filtration system, where possible. The focus has to always be on value, quality and consistency. With that in mind, make sure that you avoid any rush and ensure that you are getting the best ROI for your money. At the end of the day, the DecDust 1080 is great for small and medium workspaces, whereas the DecDust 1350 is great for a larger workshop. However, they are both an excellent option if you want to remove fine dust particles from any woodshop, not to mention they can help improve the air quality immensely and keep your employees safe. That makes them an excellent investment for any woodshop!

Shop For Dehumidifier

Abestorm 170 PPD 2,100 Sq.Ft Commercial Dehumidifier with Pump and Drain Hose | Hurricane 800

Abestorm 180 PPD 2,300 Sq.Ft Commercial Dehumidifier with Pump and Drain Hose | Hurricane LGR85

Abestorm 264 PPD 3,000 Sq.Ft Commercial Dehumidifier with Pump and Drain Hose | Hurricane 125P

Abestorm 180 PPD 2,300 Sq.Ft Commercial Dehumidifier with Pump and Drain Hose | Hurricane 850